Product Introduction

Spheroidization and High-precision classification processing

Do you have any of these challenges?

- Want to improve particle flowability

- Want to enhance the printability of pastes

- Want to increase filling volume by spheroidizing irregular particles

- Want to improve handling characteristics

- Want to narrow the particle size distribution

- Have been declined spheroidization due to small quantity

Spheroidization and High-Precision Classification

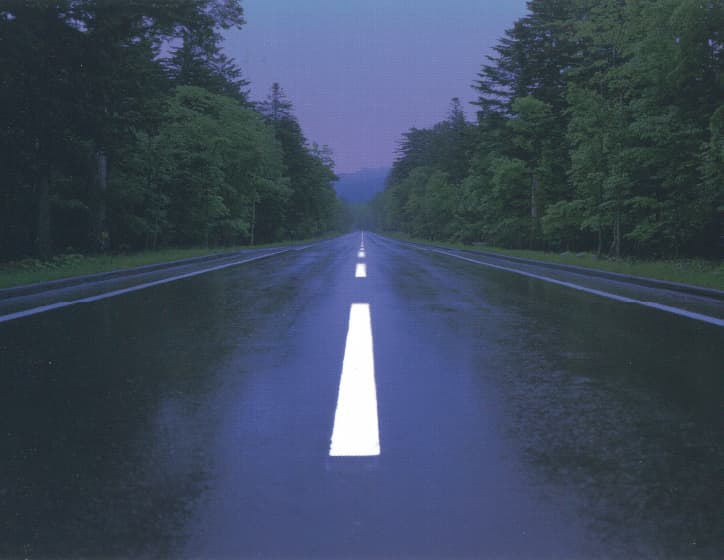

- Spherical and classification technologies utilizing 70 years of experience and expertise in glass bead manufacturing.

- Spheroidization of a wide variety of glass types.

- Small-scale trials of several kilograms are also possible.

- Classification technologies not limited to glass.

Case Studies

(1) : Spheroidization of Ceramics for Electronic Components

To improve the functionality of ceramics used in electronic components, spheroidization was performed to increase the packing density of irregularly shaped particles.

We successfully spheroidized single-micron particles, resulting in confirmed performance improvements.

In addition to this case, we have extensive experience in spheroidizing various single-micron particles.

(2) : Spheroidization of Ceramic Powder in the Research Stage (Small-Scale Project)

We successfully spheroidized a research-stage ceramic powder that was too small in quantity for other companies to handle.

After receiving less than 1 kg of raw material, we conducted spheroidization trials and provided sample beads for evaluation.

(3) : Spheroidization of low-melting-point glass with suppressed component volatilization

Low-melting-point glass with a melting point of approximately 600°C and a glass transition temperature (Tg) of 350°C or less was spherically shaped.

Although there were concerns about the volatilization of specific elements, spheroidization was successfully achieved without any component changes through temperature control.

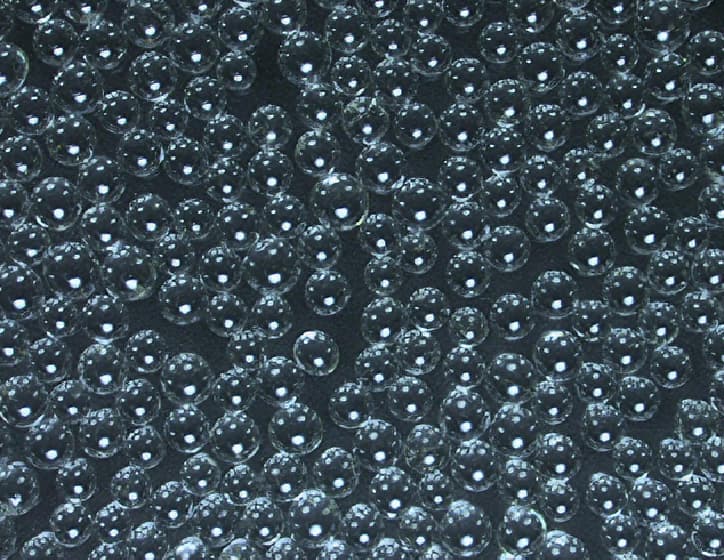

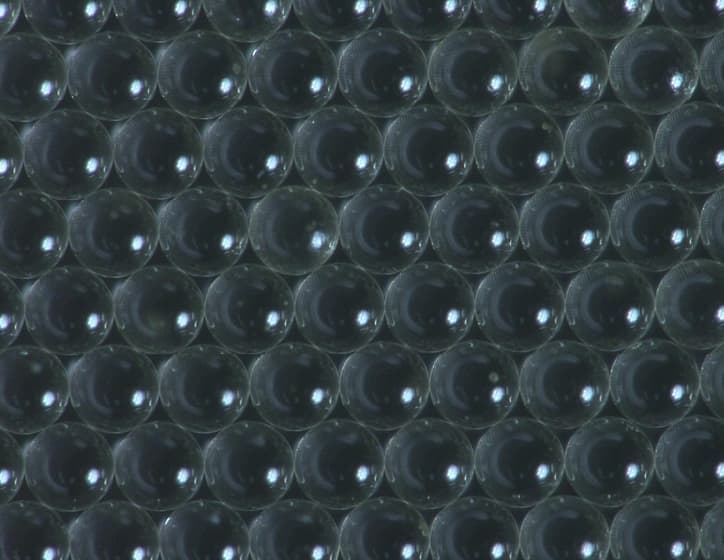

(4) : High-Precision Classification of Ceramic Balls

Commercially available ceramic balls had a wide particle size distribution, which posed a challenge.

Using our high-precision classification technology, we reduced the coefficient of variation (CV) from over 10% to below 5%.

We look forward to hearing from you.

If you're considering processing, feel free to contact us anytime.