Product Introduction

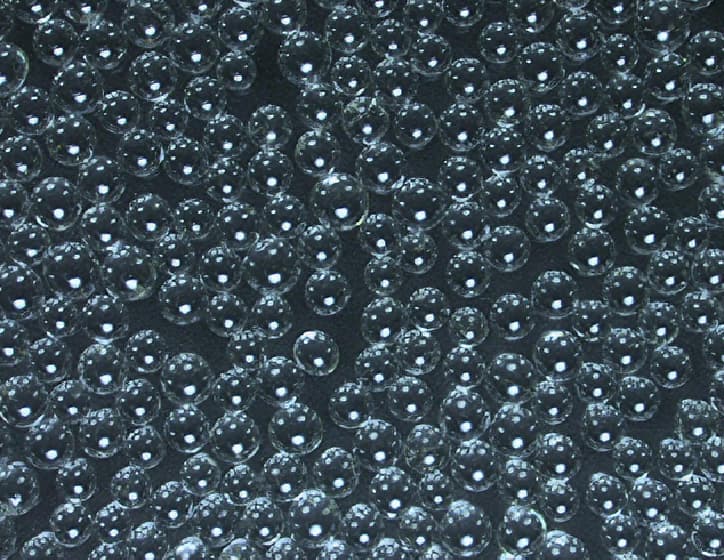

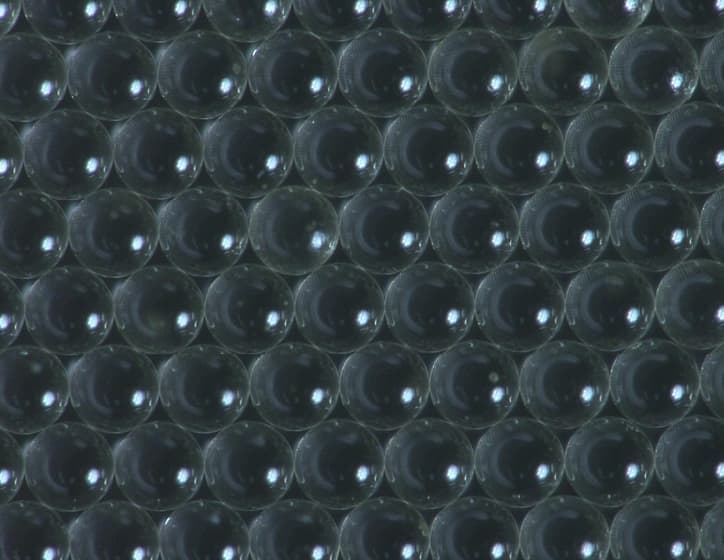

High-Precision UNIBEADS

Features

- True spherical glass microparticles feature a uniform and monodisperse particle size distribution, making them ideal as spacers for gap control and film thickness adjustment.

- They are especially suitable for applications requiring transparency, heat resistance, load-bearing capability, and electrical insulation.

- A wide selection of particle sizes is available to meet diverse needs.

- UNIBEADS can also serve as an alternative to silica or resin beads.

Characteristics

| Raw Material | Soda Lime Glass |

| Specific Gravity | 2.5 |

| Refractive Index | 1.52 |

| Compressive Fracture Load(N)*1-100μm | 7.6 |

| Compressive Fracture Load(N)*1-1,000μm | 206 |

*1: Compressive Fracture Load is a value measured by our laboratory.

Items

| Produt Name | Average Particle Size±α (㎛) |

Standard Deviation:δ | CV value | Particle Size Measurement Method |

|---|---|---|---|---|

| SPL-30 | 30.0±2.0 | 2.0 or less | 6.7% or less | Coulter Method |

| SPL-50 | 50.0±2.0 | 4.0% or less | ||

| SPL-70 | 70.0±3.0 | 3.0 or less | 4.3% or less | |

| SPL-100 | 100.0±5.0 | 3.0% or less | ||

| SPL-150 | 150.0±5.0 | 6.0 or less | 4.0% or less | |

| SPL-200 | 200.0±10.0 | 3.0% or less | ||

| SPL-300 | 300±10 | 10 or less | 3.3% or less | Caliper Method |

| SPL-400 | 400±30 | 2.5% or less | ||

| SPL-500 | 500±40 | 20 or less | 4.0% or less | |

| SPL-600 | 600±50 | 3.3% or less | ||

| SPL-800 | 820±20 | 25 or less | 3.0% or less | |

| SPL-1000 | 1030±30 | 2.4% or less | ||

| SPL-1200 | 1220±30 | 30 or less | 2.5% or less | |

| SPL-1500 | 1500±30 | 40 or less | 2.7% or less | |

| SPL-2000 | 2000±50 | 50 or less | 2.5% or less |

We also accept consultations for particle size glass beads and sharpened products other than the above.

Please contact us for details on high precision glass beads.

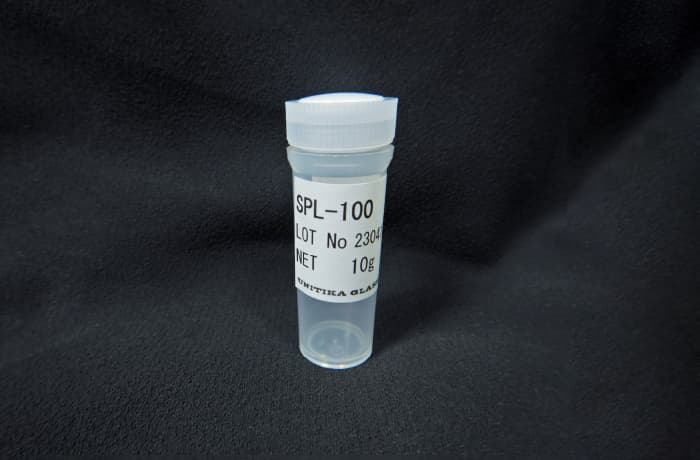

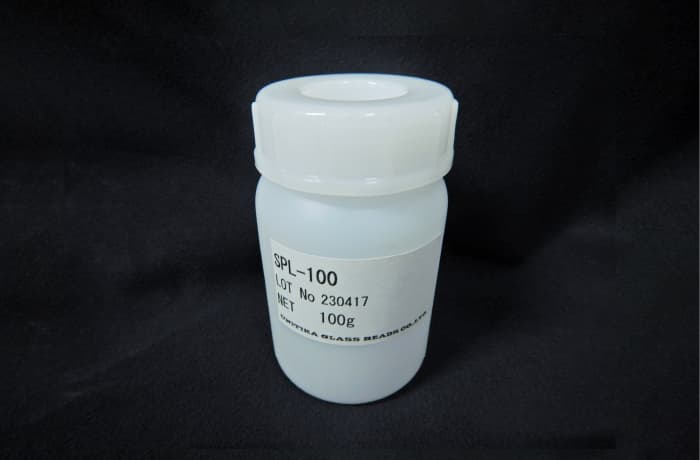

Type of Packing

10g/Bottle

100g/Bottle

Application Example

(1) Standard Sample

It is perfectly spherical, has uniform particle size distribution, and provides good reproducibility when measuring particle size distribution.

It is also suitable for particle size comparisons.

- Standard sample for calibration or inspection of particle-size distribution measuring devices, sieves, and filters

- Particles for size comparison during microscopic observation

- Foreign matter sample for quality inspection

(2) Spacer (gap control material)

By mixing glass beads with adhesive, a gap can easily be formed when gluing.

- For various parts

- For optical components

- For electronic components

- For precision parts