Product Introduction

UNIBEADS for Plastic Filler

Features

- By incorporating UNIBEADS as a filler into composite materials such as plastics and rubber matrices, various functional properties can be added.

- Thanks to their spherical shape, they provide excellent packing and flow properties, which makes processing easier and ensures uniform functionality throughout the material.

- Their isotropic nature prevents anisotropy in molded products and helps reduce warping.

- Being made of glass, they are transparent and exhibit excellent heat resistance, chemical resistance, and electrical insulation.

- UNIBEADS are also a sustainable product made from recycled glass.

Characteristics

| MF Series | E Series | |

|---|---|---|

| Raw Material | Borosilicate Glass | Alumino Borosilicate Glass (E-Glass) |

| Specific Gravity | 2.3 | 2.6 |

| Refractive Index | 1.49 | 1.56 |

Items

| MF Series (New Product) |

E Series | Main Particle Size (μm) |

|---|---|---|

| UBS-0005MF | UBS-0005E | - 5 |

| UBS-0010MF | UBS-0010E | - 10 |

| UB-01MF | - | - 38 |

| - | UB-02E | - 45 |

* Please contact us for particle sizes other than the above.

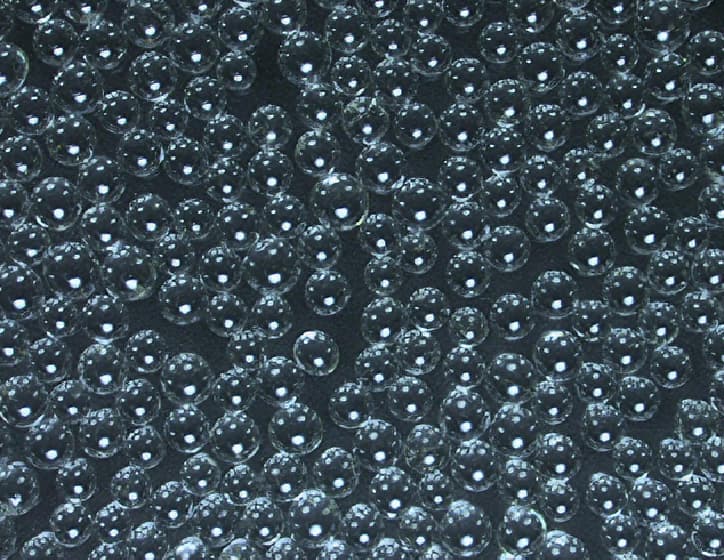

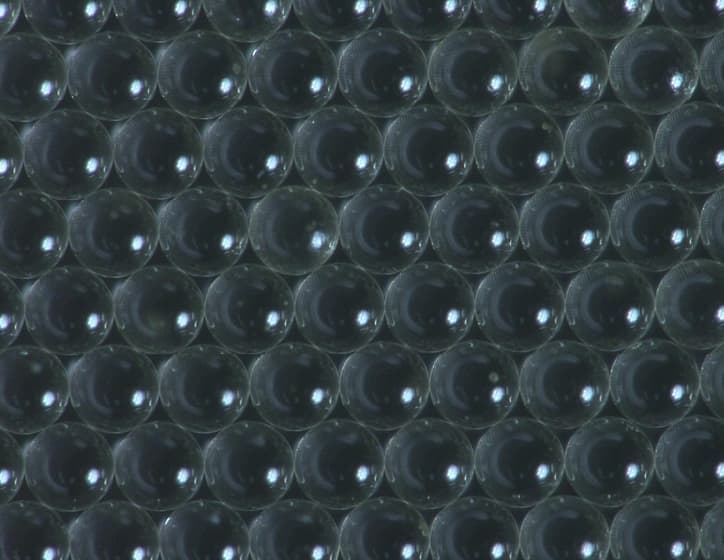

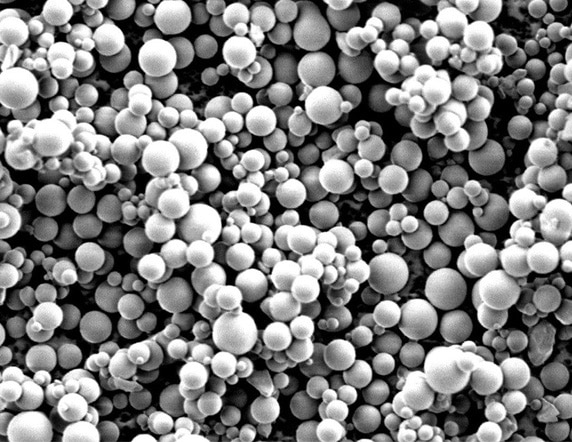

Particle Size Distribution Image

* SEM Image

Surface Treatment

Optimal silane coupling treatment is performed according to the resin type.

| Symbol | Coupling Agent | Compatible Resins |

|---|---|---|

| A | Amino silane | Epoxy, Phenol, Melamine, Fran, Polyamide, Polyester, PC, Polyurethane, NBR, Neoprene Rubber, Chloroprene Rubber, Acrylic, ABS |

| G | Glycido silane | Epoxy, Phenol, PVC, Polyester, Butyl rubber, NBR, SBR |

| AC | Acrylic silane | Unsaturated polyester, Acrylic, EPM/EPDM, Polyolefin(PE,PP) |

* The table above is only a guide. The optimum treatment agent depends on the condition of functional groups in the resin.

Type of Packing

- Paper Bag:

10kg - 25kg

(Standard number of package for filler application varies depending on particle size.)

New Product

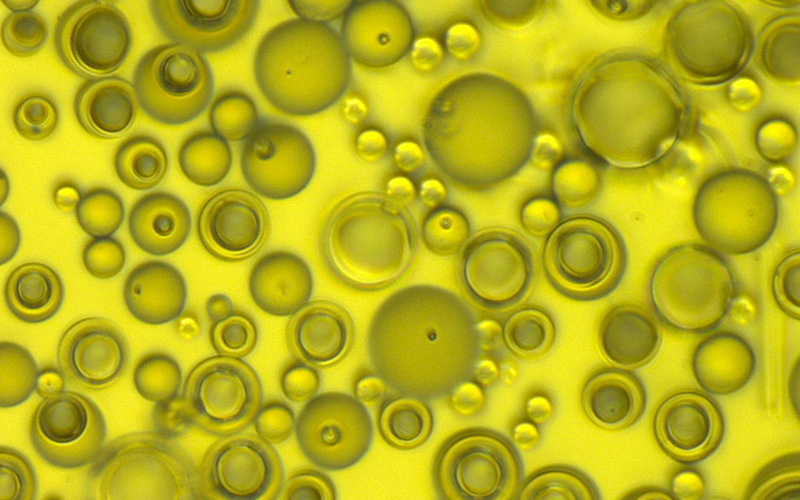

- We have developed hollow glass beads.

- Compared to conventional glass beads, they offer approximately 30% lower specific gravity.

- They are also more resistant to mechanical stress, making them less prone to cracking.